Electrostatic Discharge,ESD It is mainly used in the anti-interference experiment of electronic product equipment on human electrostatic discharge model. Electrostatic discharge generator is divided into electrostatic generator and electrostatic discharge generator. The output of electrostatic generator is either positive or negative charge, or positive and negative charges can be freely converted, and the voltage bipolar high-precision output is continuously adjustable, so electrostatic discharge generator can be used for electrostatic discharge test of most electrical and electronic equipment.

Test standards; In order to test whether the electronic equipment can work normally when it is subjected to external electrostatic discharge, the International Electrotechnical Commission standard IEC61000-4-2 Electrical Compatibility (EMC) - Part 4: Testing and measurement techniques - Section 2: Electrical discharge immunity test Basic EMC Publication has been equivalently converted into the only test equipment of the national standard GB/T 17626.2-2006 Electromagnetic Compatibility Testing and Testing Techniques Electrostatic Discharge Immunity Test.

In IEC61000-4-2 Electromagnetic Compatibility (EMC) - Part 4: Testing and Measurement Techniques - Part 2: Electrostatic Discharge Immunity Test, it is equivalent to the Chinese standard GB/T 17626.2-2006 Electromagnetic Compatibility Testing and Testing Techniques Electrostatic Discharge Immunity Test.

The scope of this part of GB/T 17626 specifies the immunity requirements and test methods of electrical and electronic equipment subjected to electrostatic discharge directly from the operator and its operator to adjacent objects, and also specifies the scope and test procedures of test levels under different environment and installation conditions.

Electromagnetic compatibility testing and testing technology Electrostatic discharge immunity test

Terms and definitions defined in GB/T 4365-2003 and the following----------

Air discharge method ;

A test method in which the charging electrode of the test generator is close to the equipment under test until it comes into contact with the equipment under test.

Antistatic material;

The material that has the characteristics of minimum charge generation when the same material or other similar materials are rubbed or separated from each other.

Contact discharge method ;

A test method in which the electrode of the test generator keeps in contact with the equipment under test and is excited by the discharge switch in the generator.

Coupling plane ;

A piece of metal or metal plate is used to simulate the electrostatic discharge of objects near the equipment under test.

HCP is horizontal coupling plate; VCP is a vertical coupling plate.

Direct application

Discharge the EUT directly.

Electromagnetic compatibility EMC;

The ability of the equipment or system to work normally in its electromagnetic environment without causing unbearable electromagnetic disturbance to anything in the environment.

Electrostatic discharge; ESD;

Charge transfer caused by close or direct contact between objects with different electrostatic potentials.

Energy storage capacitor ;

The capacitor in the electrostatic discharge generator is used to represent the capacitance when the human body is charged to the test voltage.

Ground reference plane;

GRP is a conductive plane whose potential is used as a common reference potential.

Holding time ;

Before discharge, the time interval that the test voltage drops by no more than 10% due to leakage.

Immunity (to a disturbance) ;

The ability of the device, equipment or system to face electromagnetic interference without degrading the operation performance.

Indirect application ;

Discharge the coupling plate near the EUT to simulate the discharge of personnel to objects near the EUT.

Rise time ;

The time that the instantaneous value of the pulse rises from 10% of the pulse amplitude to 90% for the first time.

Test level

in the experiment, contact discharge is the preferred choice, and air discharge is only selected when it cannot be used. The voltage of each test method is given in Table 1. Because of the different test methods, the voltage of each method is different, but it is not to say that the voltage of the two methods is the same. There are still great differences between them.

Table 1 Test level

Test generator

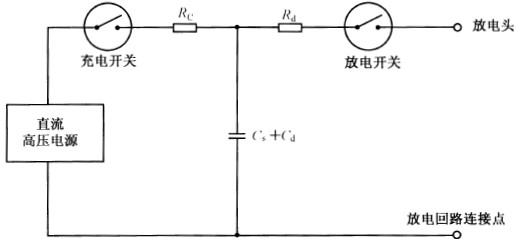

The main parts of the test generator include:

Charging resistance Rc;

Energy storage capacitor Cs;

Distributed capacitance Cd;

Discharge resistance Rd;

Voltage indicator;

Discharge switch;

Charging switch;

Discharge circuit cable;

Power supply unit;

Replaceable discharge electrode head (see Figure 4);

Figure 1 Schematic diagram of electrostatic discharge generator

The circuit principle is to first close the DC high-voltage source of the charging switch to charge the CS+Cd (Cd in the figure is the distributed capacitance between the generator and the surrounding) capacitor, and then open the charging switch (the load resistance Rc protects the charging circuit during the charging process) when the capacitor is saturated, and then close the discharge switch to form a discharge loop to release the output through the discharge head (the load Rd plays a protective role in the output circuit).

Table 2 General specifications

Table 3 Contact discharge current waveform parameters

Figure 2. 4 kV ideal contact discharge current waveform

The ideal waveform equation I (t) in Figure 2 is as follows:

Where;

Characteristics of electrostatic discharge generator

The test generator shall meet the specifications in Table 2 and Table 3. Figure 2 shows the ideal current waveform and measurement points specified in Table 2 and Table 3. It can be verified according to the calibration of current measurement system and the method of discharge current measurement.

Calibration of current measurement system and discharge current measurement

The current target is installed in the center of the vertical calibration plane. The discharge circuit cable (grounding wire) of the electrostatic discharge generator shall be connected at a place 0.5 m below the target at the bottom of the plane center. The ground wire shall be pulled back at the center of the cable to form an isosceles triangle. During calibration, the ground wire should not be laid flat on the floor.

Install the following steps to verify whether the current waveform of the electrostatic discharge generator meets the specifications. Record the shape of the wave and measure the following parameters:

Ip peak discharge current, in amperes (A);

I30 starts at 0.1 times the current value of the peak current I,, and the current value after 30 ns, in amperes (A);

I60 from peak current I!, The current value after 60 ns starting from 0.1 times the current value, in amperes (A);

T r The rise time of the current, in nanoseconds (ns).

表4接触放电校准程序

Figure 3 Typical configuration of ESD generator performance calibration

Note 1: The generator should be installed on a tripod or equivalent non-metallic low-loss support.

Note 2: The generator should be powered in the same way as the test.

Note 3: Compared with the reverse configuration in Figure 3, it can also be used.

If it can be proved that the indirect coupling path on the rat-measuring system will not affect the calibration results, it is unnecessary to shield the oscilloscope.

If the oscilloscope results are not triggered in the following cases, the calibration system can be considered to have sufficient immunity (that is, it is unnecessary to use a Faraday cage):

The trigger level of the oscilloscope is set at 10% of the minimum test level of 1000, and the electrostatic discharge generator discharges the outer circle (not the inner circle) of the target at the highest level.

Figure 4 ESD generator discharge electrode

Use the same generator for the air discharge test method, and the discharge switch must be closed. The generator shall be equipped with a round head as shown in Figure 4a). Because the same ESD generator is used, there are no more specifications for air discharge mode.

The cable length of the discharge circuit in the test generator is (2 ± 0.0S) m, and its composition shall make the generator meet the requirements of waveform. The length of the discharge circuit cable is from the ESD generator body to the end of the connection point. It shall have sufficient insulation to prevent discharge current from flowing to personnel or conductive surface without passing through its port during electrostatic discharge test.

The discharge circuit cable used in the test shall be the same or equivalent to the cable used in the calibration.

If the 2m long discharge circuit cable is not long enough (for example, the higher equipment under test), the cable not longer than 3m can be used. The cable used in the test shall conform to the waveform specification.

Verification of ESD layout

To verify the correct ESD test layout, one verification method is to observe the small spark generated when the coupling plate is discharged in the air at the low voltage setting and the large spark at the high voltage setting. Before this verification, verify the connection and location of the grounding strap.

Basic principle: Because the waveform parameters from the ESD generator usually do not change slightly (for example, the rise time and duration of the waveform do not drift), the most likely failure is that the ESD generator voltage is not sent to the discharge electrode, or the voltage control fails. Damage, looseness or missing of cables, resistors or connecting wires in the discharge path will lead to failure to discharge.

试验布置

Figure 4 Example of table equipment test arrangement during laboratory test Figure 5 Example of floor type equipment test layout during laboratory test

Finally, how to test ESD equipment? ESD products can only be delivered to our service providers after passing these tests. Only strict testing and hard research and development can ensure the quality of our products, make service providers feel at ease and have a good user experience.

Domestic EMC instrument and equipment - international high-end instrument and equipment agent, customizable, EMC industry research and development and manufacturing, electrostatic discharge, automotive electronics, home appliance lighting, medical preference.

Shenzhen Hodal Instrument Co., Ltd. is a domestic manufacturer of high-end equipment and has been committed to leading international and domestic EMS instruments and equipment for several years.